The growing population and expanding urbanization are increasing the demand for high-quality building materials. In this regard, Uzbekistan’s building materials industry is developing dynamically: modern technologies are being introduced, and the production of highly efficient products is being established.

One example is the enterprise producing aerated concrete blocks operating in Namangan Free Economic Zone and financed by Turonbank. As part of the $40 million project, technologies from China, Germany, and Denmark have been introduced at the enterprise, ensuring high product quality and efficiency.

For instance, aerated concrete blocks produced using German technology allow for significant energy savings. Buildings constructed with such blocks do not require additional external thermal insulation, while indoor heat loss is reduced fourfold. As a result, electricity costs decrease by up to 45 percent.

In production, grade 550 cement from Namangan Cement plant, which is part of the Megaton enterprise, is used, enabling the formation of a value-added chain. The enterprise has created 500 new jobs.

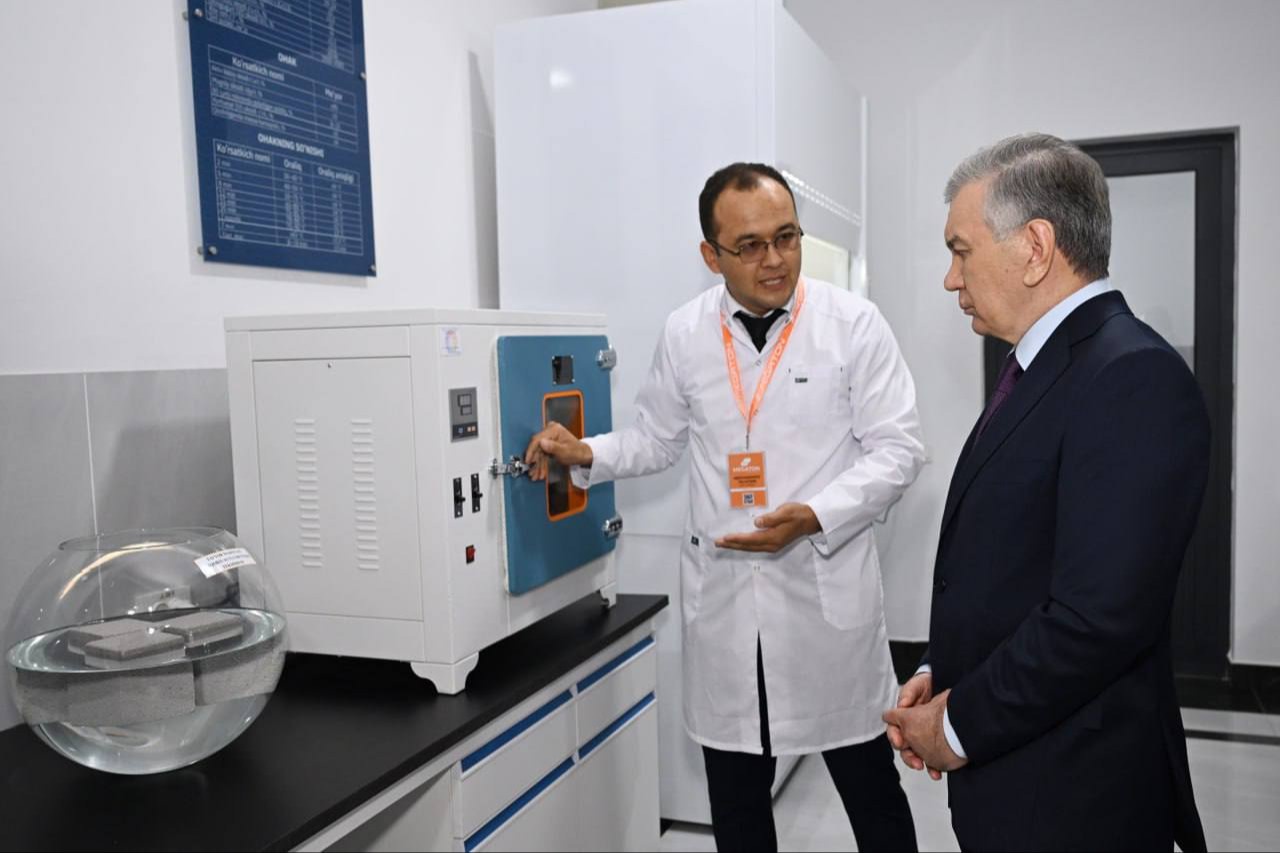

The Head of State inspected the production workshops, laboratories, and finished products. Managers provided information on product quality and resistance to high and low temperatures.

“It is important that our construction industry keeps pace with the times and produces high-quality products”, the President emphasized. “Such innovative technologies must also be introduced in other sectors where the share of imports remains high. This will foster healthy competition in the market, expand consumer choice, and create new job opportunities. We will continue to support enterprising entrepreneurs”.

The plant is capable of producing up to 600,000 cubic meters of products per year, which will cover about 28 percent of the region’s demand for bricks.

As part of the second stage of the project, plans include the localization of autoclaved aerated block production, as well as specialized adhesive and plaster mixtures.